Laser Marking and Paint removal for Backlit | Electrical and electronics components

Laser Marking and paint removal for backlit on Electrical and electronics components: MCB, Bulb, PCB, SMD, Energy meters, Wires, electrical mounting, mobiles, computer and its accessories like Keyboard and mouse.

The electrical and electronic industry is growing at a greater pace. Electrical and power electronics market will worth $44.2 billion by 2025. Electrical and electronics brands like ABB, Schneider electrics, Philips and there are many in the market. Laser Application on their components of different substrates becomes a challenge. The electronic components are getting smaller day by day. Apple manufacturing unit is coming to India, all big brands are shifting there manufacturing to India. these are some of the good news for the Indian economy. Where Markolaser Stands for providing all Industrial Laser Solution to such big brands. Every day a new electrical and electronics product is launched, which is the part and parcel of life. Markolaser is the partners of almost all the big brands in India it may be A Switch gears company like ABB or a Company like Panasonic. We are always there to serve and help them in any laser application. Automating their production and helping them to trace and track every product throughout there life cycle.

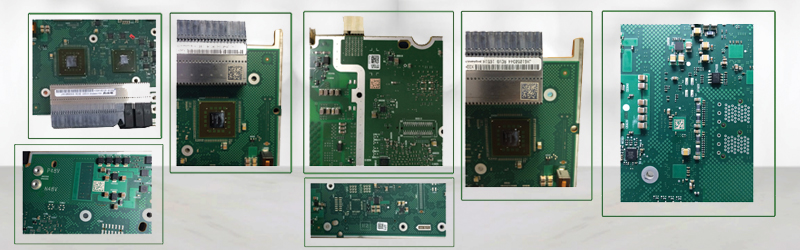

Laser Marking on Electronic Semiconductor PCB, Datamatrix(DPM) and Serialization of Printed Circuit Board

These Printed circuit board, electronics Semiconductor chip are Laser marked with DPM Code and Serial Code for traceability and accurate identification. It assures quality at every stage of life or processes the PCB has gone through. The 2D - Datamatrix code and the alphanumeric character are customizable according to customers requirements. Any complex size of code on the surface of the semiconductor can be marked with great precision. The Laser Marking is carried out with all Industrial ISO/IEC standards.

Laser Marking on Semiconductor MCB & Switchgears

The switch gears like contactors, MCB housing are Laser Marked with its ratings and traceability barcode, QR code or data matric code, Simple alphanumeric code, and any customizable data. The Permanent marking of the logo for Branding has become an essential part of any industry laser Marking is a cost-beneficial and convenient process to satisfy any requirement. The premium quality marking with premium laser marking machines defines Markolaser. The semiconductor material of MCB is very complex to mark, need a lot of engineering research and development. We have more than 30 years of experience. We have Automated the Laser marking process according to the substrate and different heights of laser marking.

Laser Marking of Circuit Diagram & rating on Energy meter

Laser Marking of circuit diagram, rating, traceability code on the transparent PP Energymeter cover. Opaque, dark, clean and crisp laser marking without any bur. Laser Marking of DPM to trace and trace the data. Industrial machine-readable Datamatrix code has made life easy for all our customers.

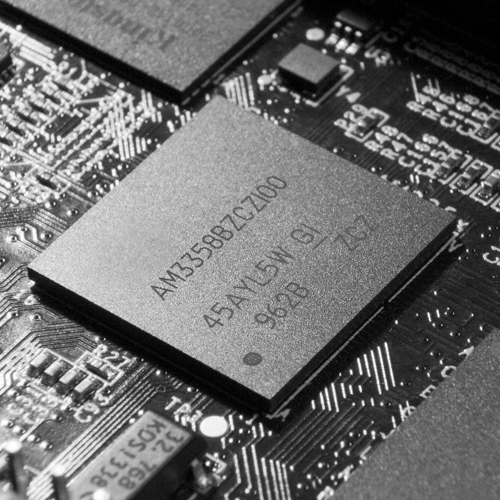

Laser Marking on Surface-mounted semiconductor Devices Like Diode, Capacitor, inductor

Surface-mounted devices are going smaller in size. The construction of the SMD parts is very difficult. And Laser marking on these Semiconductor part needs to be done with greater precision. Most parts are smaller in size and fine/sharp/precise marking on these parts are very important. This Surface-mounted device of PCB might be of different material, metals ceramic, epoxy resins, silicone. There marking can be a data matrix code, a serial code or the alphanumeric code, logos, customized data, the laser marking must be applied with a high degree of precision.

Laser Marking Automation of LED Bulb

Automatic Laser marking of Bulb on the circumferential surface area.Manual loading of bulbs, Dual head laser marking of the logo on one side and DataMatrix code on the other side. Laser marks with high speed. Highly opaque dark marking on the bulb surface. Automatic unloading facility makes the automation more cost-effective and efficient with the minimal workforce. This leads to cut down of cost on the worker. Which would be recurring money spent on Automation.

Fully Automatic Robot Integrated, Laser Marking of Variable Data on Electric Contactors

It is a fully automatic pad printing and laser marking machine. In this automation pad printing machine prints on 3 positions with 2 colours. Laser marking head is employed for marking MCB ratings on its two sides. Automatic Loading of MCB and unloading of MCB has made the Automation most cost-effective and economical machine for our customer. Saves time, High production and most reliable machine for printing and laser marking on MCB. The Fixtures are built with a great milling machine in a house with engineering research and development.

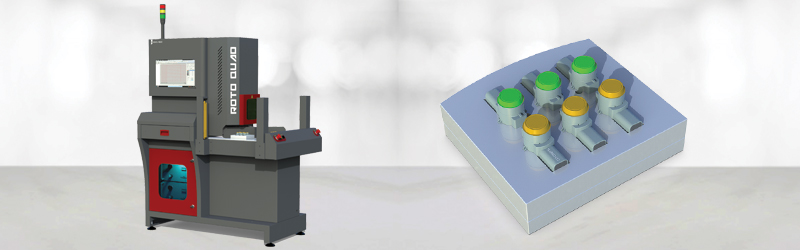

Laser Marking on parking sensors

The Laser marking solution involves a 4-station rotary table with a visual solution to mark on parking sensors. The criticality of the problem lies in the fact that marking on a parking sensor is done in multiple colours (around 42 colours). Our solution comes with an intelligent vision system which allows laser marking on the right sensor in a predefined colour matrix.

Laser Marking on (Electrical) LED Drivers

-LED-Drivers_1607333358.jpg)

It is a semi-automatic machine to mark on black painted housing of LED drivers. This automation consists of a dual laser head for marking and an intelligent customized interface that enables the machine to judge the part orientation and consequently, perform the right marking. This specialized machine comes with a complete range of trace and track features.

Fully automatic Dual Head Laser Marking System on ACBs (Air Circuit Breakers)

Laser marking of validated electrical data on two opposite faces (top and side) of the special plastic surface.

Our unique solution comes with a customized client control interface that synchronises variable data from the central server to the marking system.

The user-friendly GUI provides real-time events/alarms/live status of the machine. And, the sophisticated dual laser marking heads come with extremely specialized optical configuration, optimized to create the good, fast and legible marking effect on special plastic materials. IOT Data management Software, hardware+ sensor+ Automation.